JAKARTA, July 30, 2025 – Indonesia’s state-owned mining group MIND ID has announced plans to expand national aluminum

production capacity to 900,000 tonnes per annum (KTPA) by 2029, a threefold increase from its current 275,000 KTPA. This strategic

move aims to bridge the gap between Indonesia’s domestic supply (275,000 tonnes) and soaring demand (1.2 million tonnes),

driven primarily by electric vehicle (EV) and renewable energy sectors2.

Key Drivers of Expansion

EV and Solar Infrastructure Demand

A single EV battery pack requires 18% aluminum content, while 1 MW of solar PV production consumes ~21 tonnes of aluminum2.

Domestic aluminum consumption is projected to surge 600% over 30 years as Southeast Asia becomes a global EV manufacturing hub.

Integrated Downstream Strategy

MIND ID will deploy:

A new 600 KTPA production facility in Mempawah

Smelter Grade Alumina Refinery (SGAR) Phase II (+1 million tonnes/year capacity)

Bauxite reservoir (1.47 million tonnes/year) to secure raw materials2.

Global Innovations Reshaping the Industry

Revolutionary Russian Processing Technology

Scientists at Siberian Federal University unveiled the world’s first combined casting-rolling-pressing unit, enabling direct production

of rods/wire from molten aluminum—including scrap recycling. This slashes production costs by 30% and supports circular economy goals10.

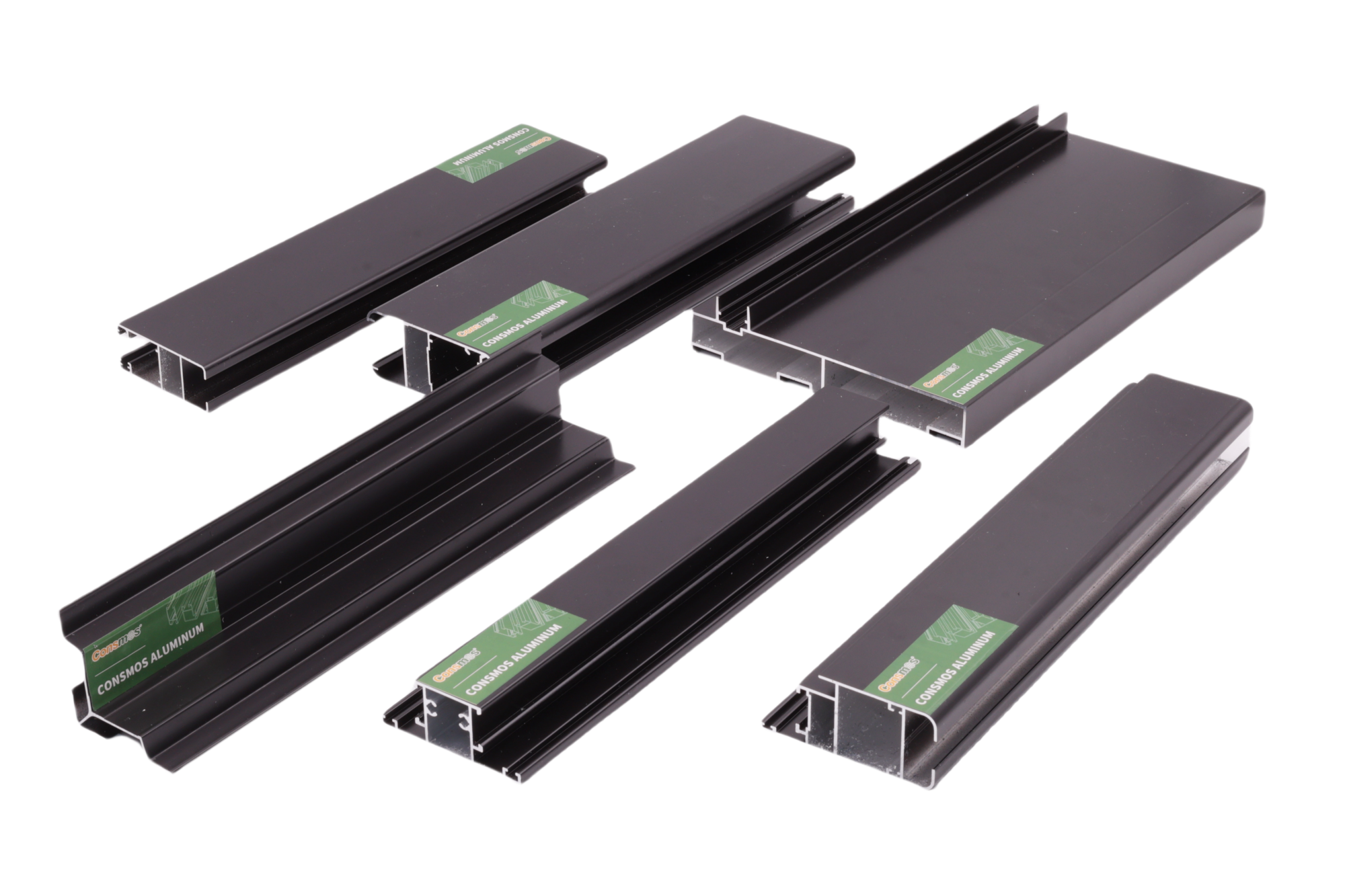

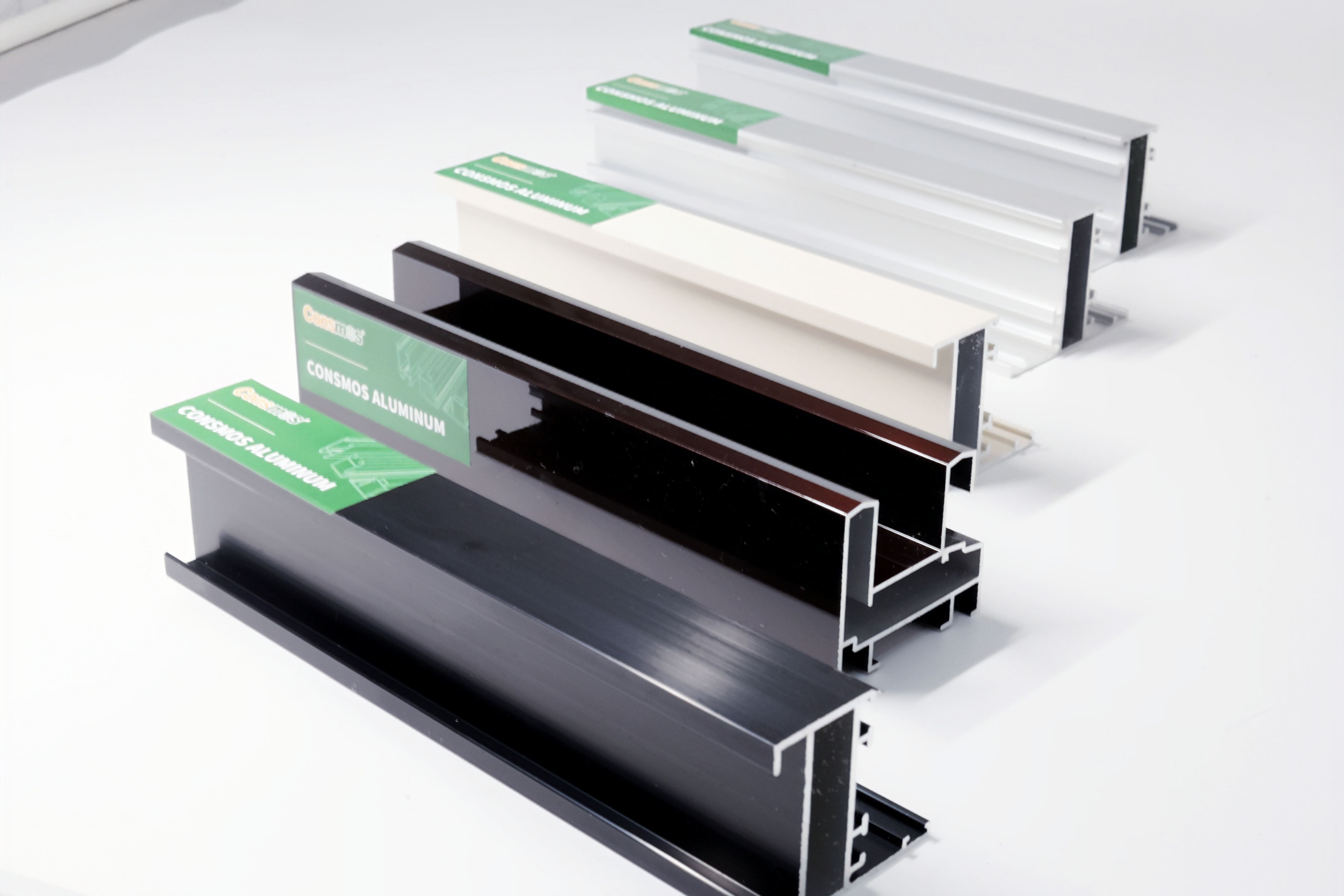

Eco-Certification Momentum

China’s Xinjiang XL Aluminium recently secured the highest-tier "Samsung" green building certification for powder-coated and insulated profiles,

validating their ultra-low VOC emissions and 0.8W/(m·K) thermal conductivity1.

Sustainability Investments Accelerate

https://example.com/recycling-plant.jpg

Figure: Recycled aluminum billets (sample). Source: CMR-Nippon JV Press Kit

India-Japan joint venture CMR Eco Aluminium (partnering with Nippon Light Metal) is pioneering low-carbon billet production using recycled scrap.

Their methods reduce energy use by 95% and emissions by >95% versus primary aluminum—aligning with the global recycled aluminum market’s

projected growth to 57 million tonnes by 20404.

Market Outlook

Despite strong demand, producers face headwinds:

LME prices rose 20% YoY in Q1 2025, but production costs squeezed margins (Alba Bahrain’s profits fell despite revenue growth)8.

Regional premiums surged (e.g., +77% YoY in the U.S.) due to tariffs and inventory shortages8.

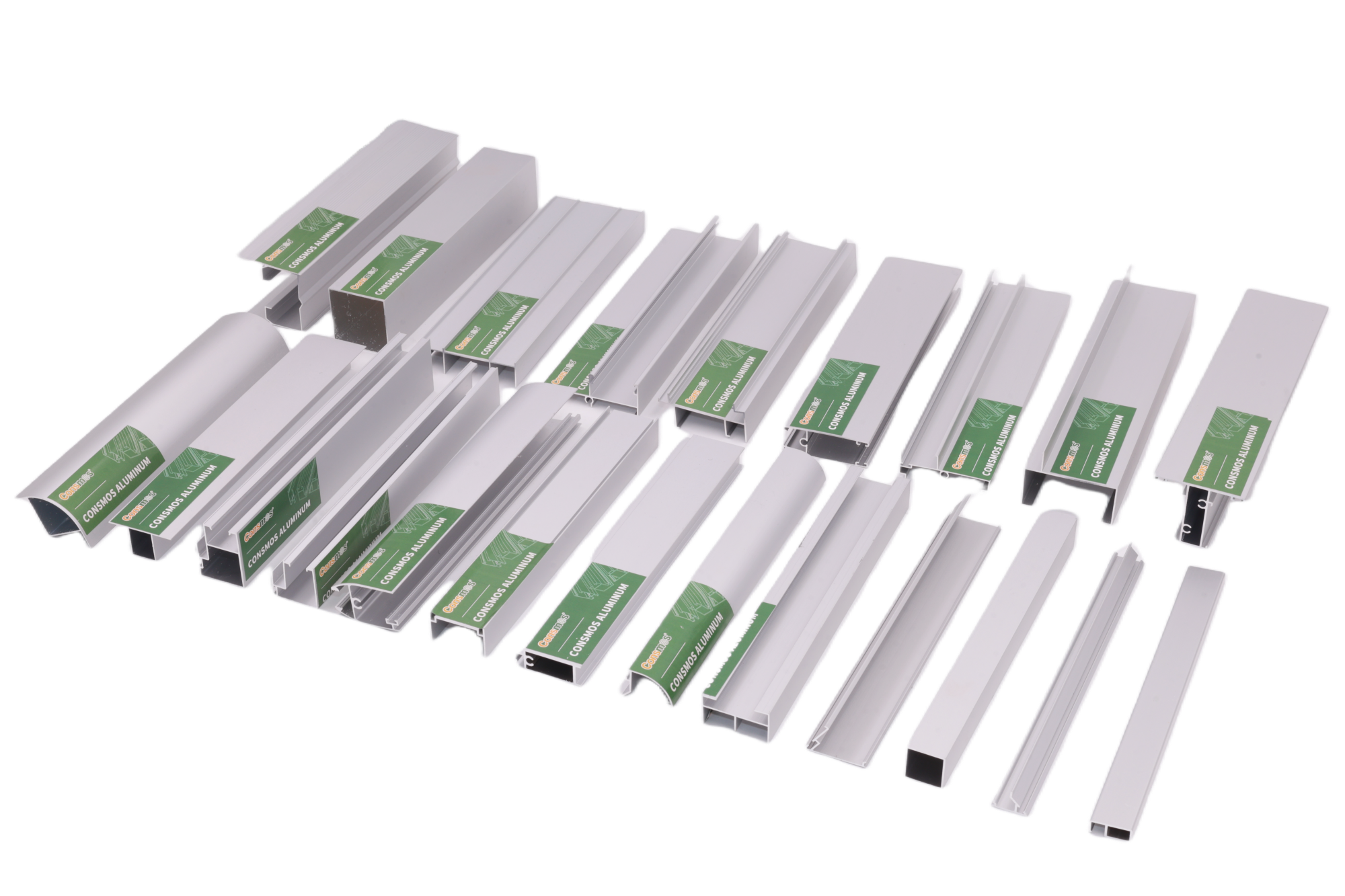

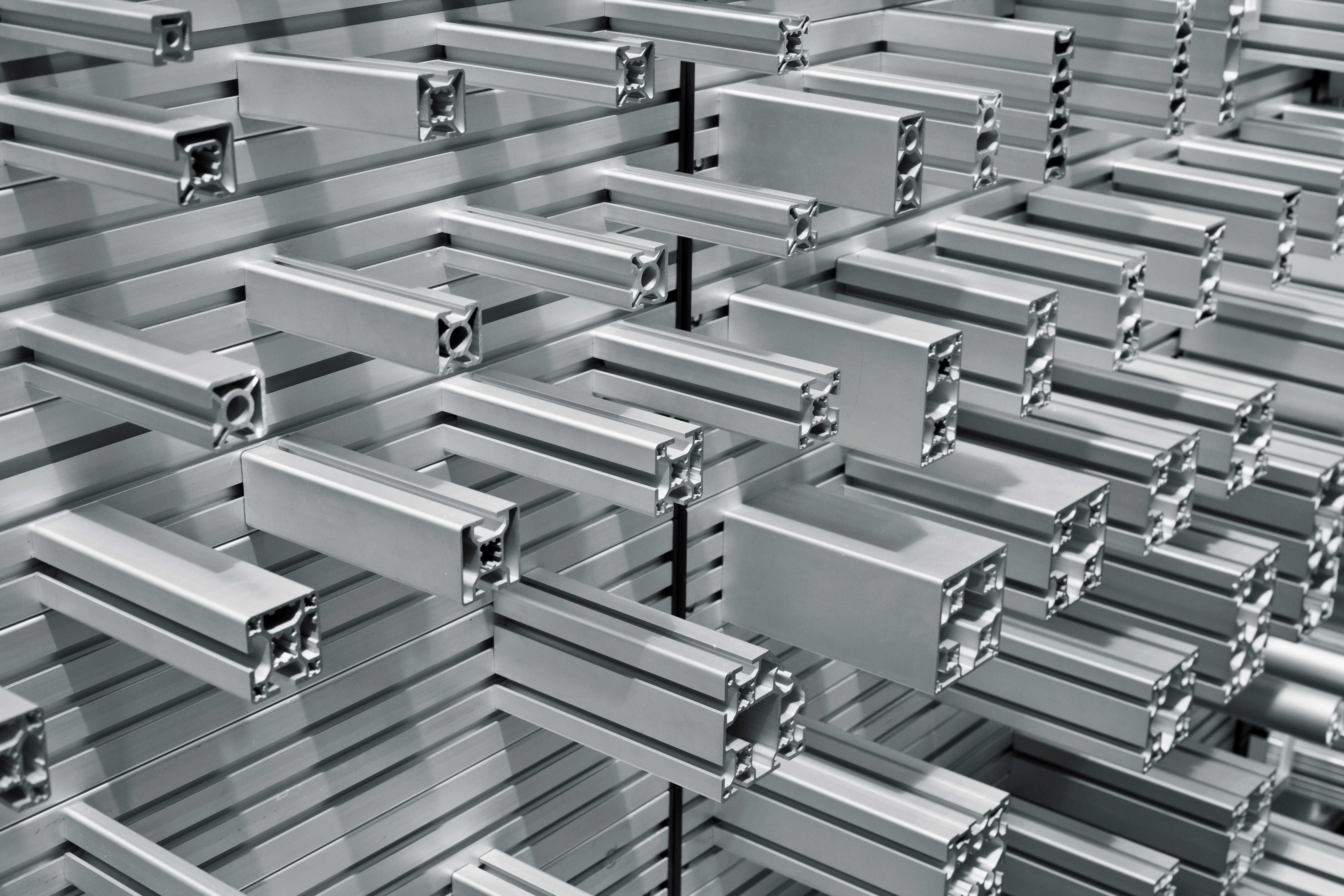

Product Innovations

Modular T-Slot/V-Slot Profiles: Jiangxi Tai’an Aluminum’s new precision profiles (±0.1mm tolerance) cut battery pack assembly time by 30%9.

Friction-Reducing Profiles: YHD’s patented "speed chain profiles" use replaceable friction strips to extend conveyor lifespan3.

Why This Matters

"Aluminum’s role in decarbonizing transport and construction makes it a critical material. Indonesia’s expansion and technologies like ingotless

processing will reshape supply chains while supporting sustainability targets."

– Industry Analyst, Metal Strategy Group

Image Implementation Guide

Section Recommended Visual

Indonesia expansion Mempawah facility renderings or map

Russian technology Lab installation close-up (see 10 for reference)

Green certification XinXL’s certified products in building applications

Modular profiles Tai’an’s T-slot assembly in EV batteries

This template combines breaking news, technical innovation, and market analysis—ideal for engaging B2B audiences. For ongoing coverage,

track MIND ID’s project milestones (next update: Q4 2025) and the Siberian technology’s commercial rollout.